Company established

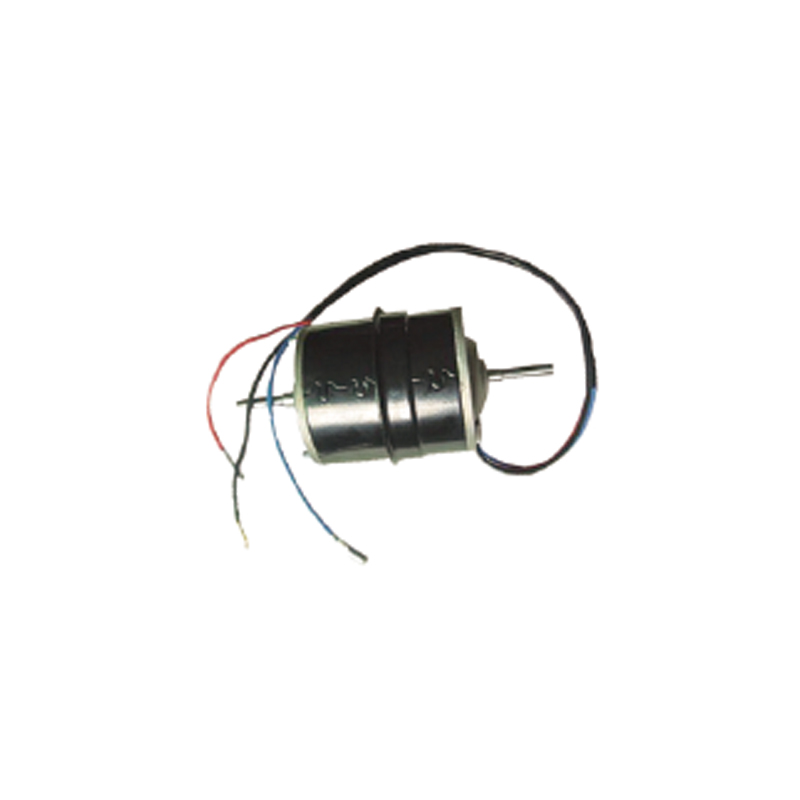

Air conditioning motors for construction machinery are specially designed for heavy-duty vehicles such as excavators, loaders, bulldozers, and cranes. As a key component in the HVAC system, these motors are built to handle challenging operating conditions and extended use. Key advantages include:

High durability: Designed with reinforced housings, high-temperature insulation, and dust- and water-resistant structures to perform reliably in demanding environments such as construction sites, quarries, or humid and hot regions.

Stable output: Provides consistent power to drive blower or condenser fans, supporting effective refrigerant circulation and in-cabin temperature control for operator comfort.

Wide voltage compatibility: Typically supports both 12V and 24V systems, with good tolerance for voltage fluctuations commonly found in construction machinery.

Low maintenance and long service life: Equipped with wear-resistant bearings and durable components (including brushless options), reducing downtime and maintenance frequency.

Flexible installation: Offered in various configurations—such as single shaft, dual shaft, or flange-mounted—to fit different HVAC layouts across machinery brands.

These motors are important for maintaining comfort and ventilation in equipment cabins under continuous or variable working conditions.